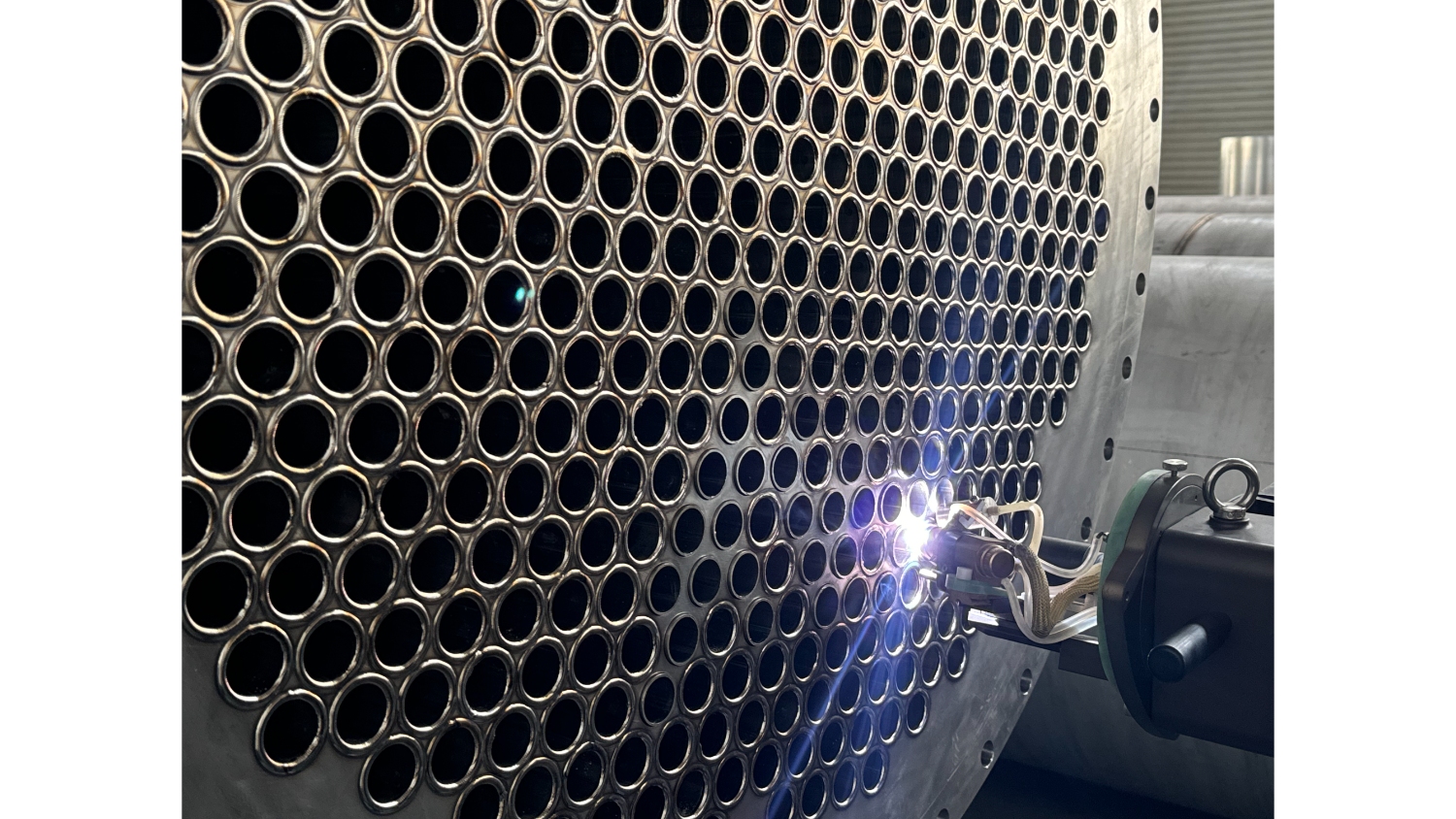

Home > Application > Orbital Cutting & Welding > Tube sheet welding TS8 equipment in 2mm thin-walled tube heat exchanger

Home > Application > Orbital Cutting & Welding > Tube sheet welding TS8 equipment in 2mm thin-walled tube heat exchanger

I. Product Overview

TS8 is an orbital welding equipment designed for tube-to-tube welding. It is mainly used for connecting tubes and tube-to-tube sheets of industrial equipment such as heat exchangers and condensers. Its core technologies include cold wire TIG welding process and orbital automation control, which can achieve high-precision and high-efficiency welding operations.

II. Technical parameters

Pipe wall thickness: 2mm.

Power supply system: equipped with P400 programmable power supply, output current 5-400A, support 380V three-phase power supply.

Functional features: integrated AVC (arc voltage control), digital parameter storage, offline programming and other functions.

Structural design: modular frame, equipped with hydraulic clamping device, supports operation in small spaces; weighs about 13kg, and is highly portable.

III. Quality verification data

The weld was 100% penetrated and no defects such as pores and lack of fusion were found

The water pressure test (1.5 times the design pressure) remained leak-free for 2 hours

The tensile test showed that the weld strength reached 98% of the parent material, and there was no crack in the bending test

The fatigue life test reached 1.5 million cycles, which is 50% higher than the traditional process

IV. Technical advantages

High-precision control: Digital closed-loop control is used to ensure the stability of welding current, speed, and gas flow, and uniform weld formation.

On-site adaptability: The hanging design combined with the expansion device positioning technology can complete welding without disassembling large components, reducing logistics costs.

Intelligent functions: Some models integrate the Internet of Things module to support remote monitoring, fault diagnosis and predictive maintenance.