Home > Application > Plate Machinning Equipment > CNC Plate Edge Milling Solutions For Tank Container Manufacture --- NT TANK

Home > Application > Plate Machinning Equipment > CNC Plate Edge Milling Solutions For Tank Container Manufacture --- NT TANK Introduction

The tank container industry requires precision, efficiency and reliability in the manufacturing process. A key aspect of tank container production is the edge milling of container components, which requires high precision to ensure proper sealing and structural integrity. This case study introduces the company's solution GMM-X8000 for customers in the tank container industry, explores the application of CNC edge milling machines in the tank container industry, and highlights its advantages and performance.

Challenges in the Tank Container Industry

Tank containers are used for transporting liquids, gases, and powders, and they must meet stringent safety and quality standards. The edge milling process is crucial for ensuring that the container's edges are smooth, precise, and free from defects. Traditional edge milling methods often face challenges such as:

Inconsistent Edge Quality: Manual or semi-automated milling can lead to variations in edge quality, affecting the container's sealing performance.

Low Efficiency: Conventional milling machines may not be able to keep up with the high production demands of the tank container industry.

High Labor Costs: Manual edge milling requires skilled labor, which can be costly and difficult to maintain consistently.

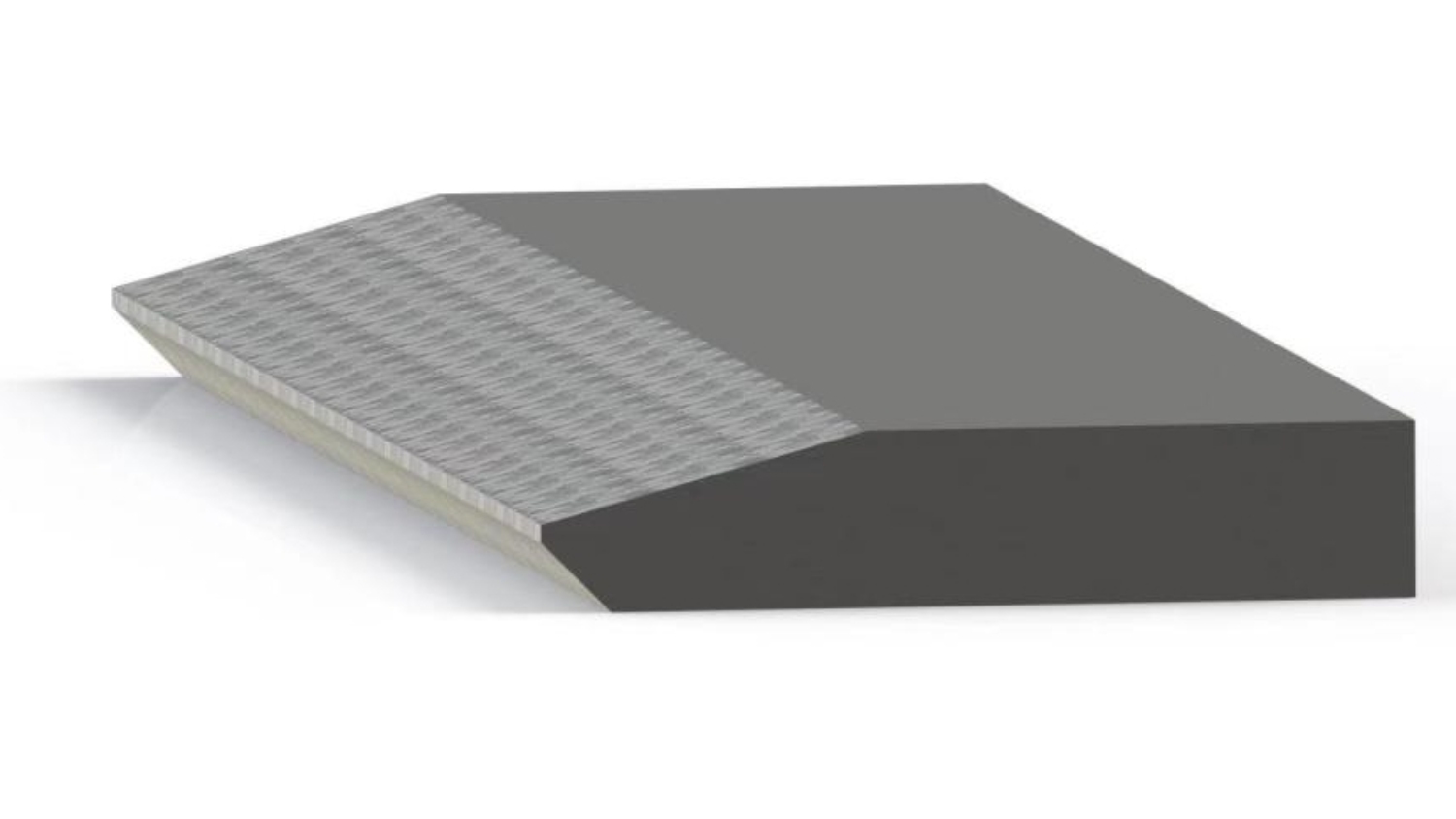

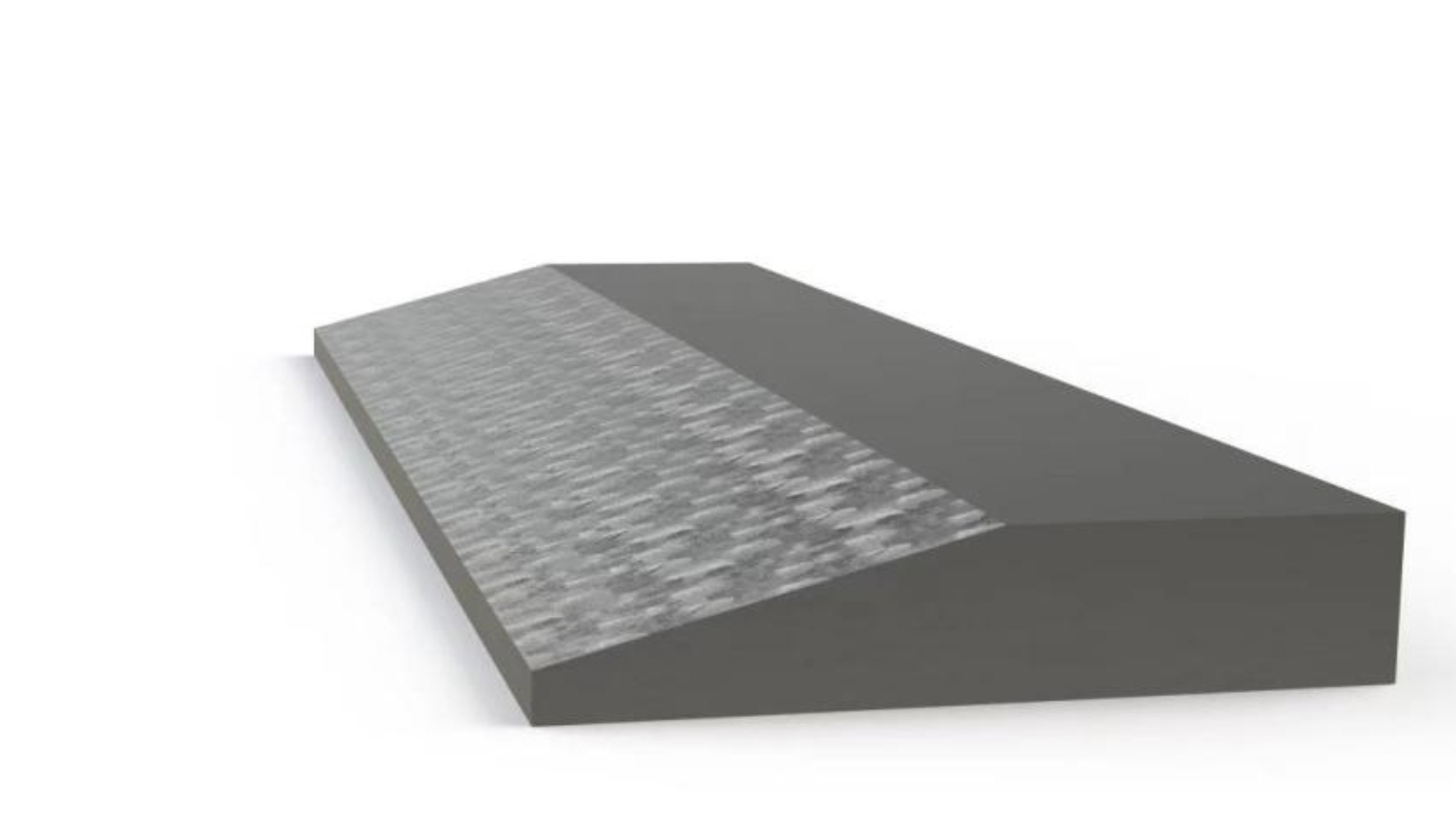

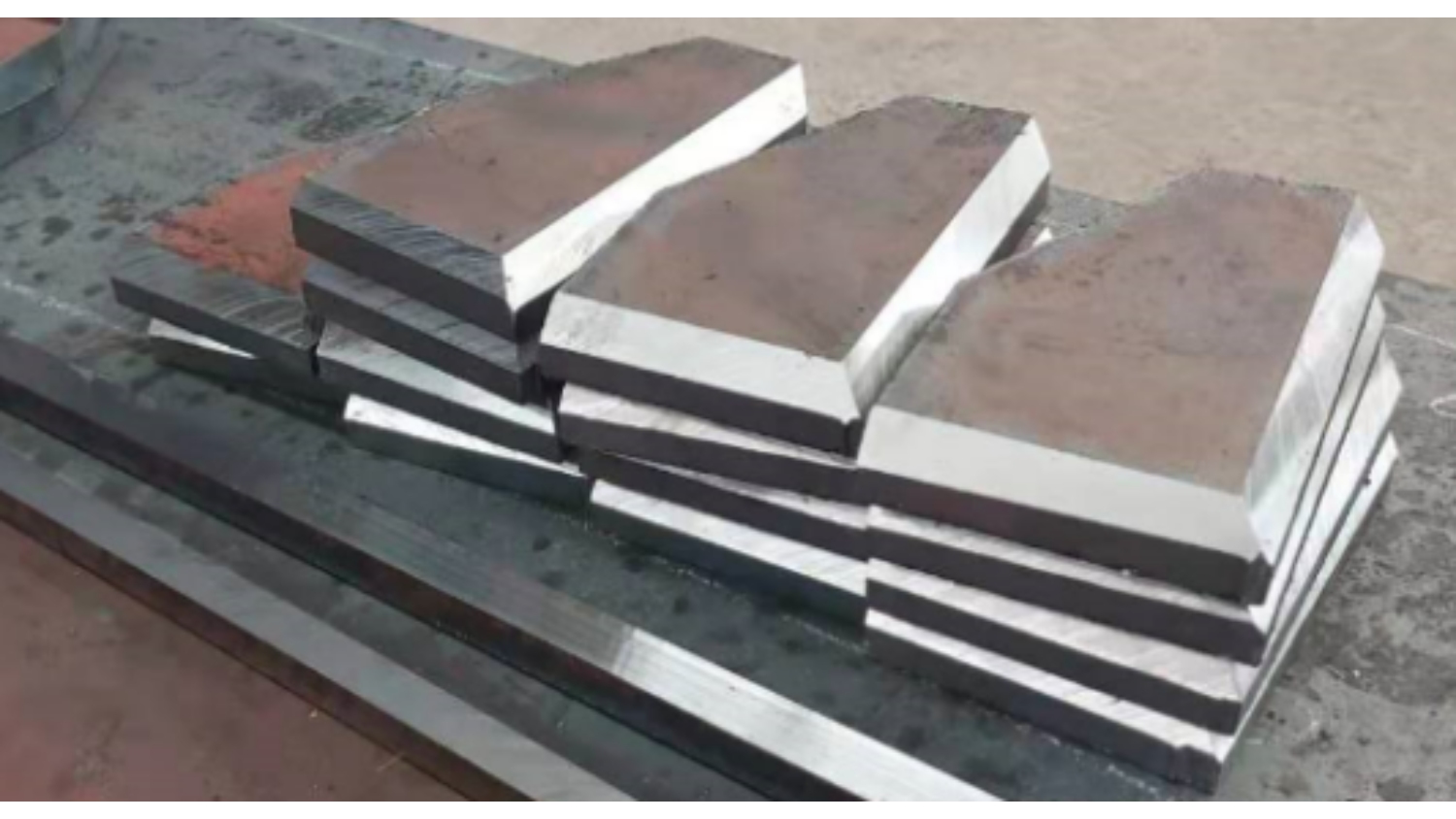

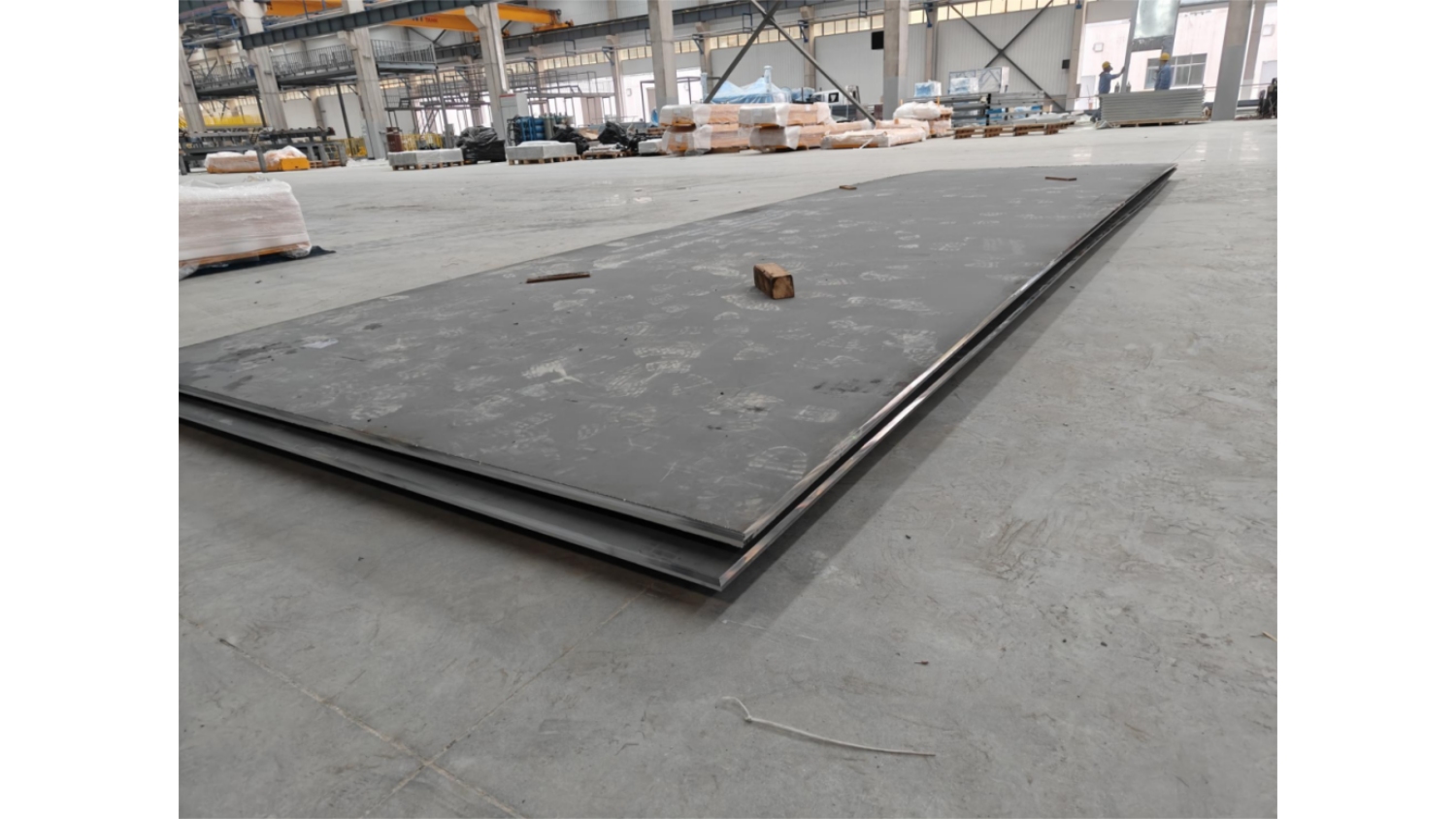

The plate material required by the customer to be processed for the production of tank containers is very hard. The material of Q345R and Q245R increase the difficulty of processing. The length of the processed plate is required to reach 8 meters, and the thickness of the steel plate is between 16-25. We have launched a new CNC edge milling machine GMM-X8000, which can solve the above problems well.

Solution: GMM-X8000 CNC Edge Milling Machine

The GMM-X8000 CNC Edge Milling Machine is specifically designed to address the challenges faced by the tank container industry. This advanced machine offers several key features that make it an ideal solution for edge milling in tank container manufacturing:

No programming required:

NODHA & GIRET has adopted the control program that has been independently designed, developed and continuously improved over the years. You only need to select the required beveling form, angle, etc. on the control panel to achieve precision processing of various complex beveling shapes without complicated programming.

Automated Operation:

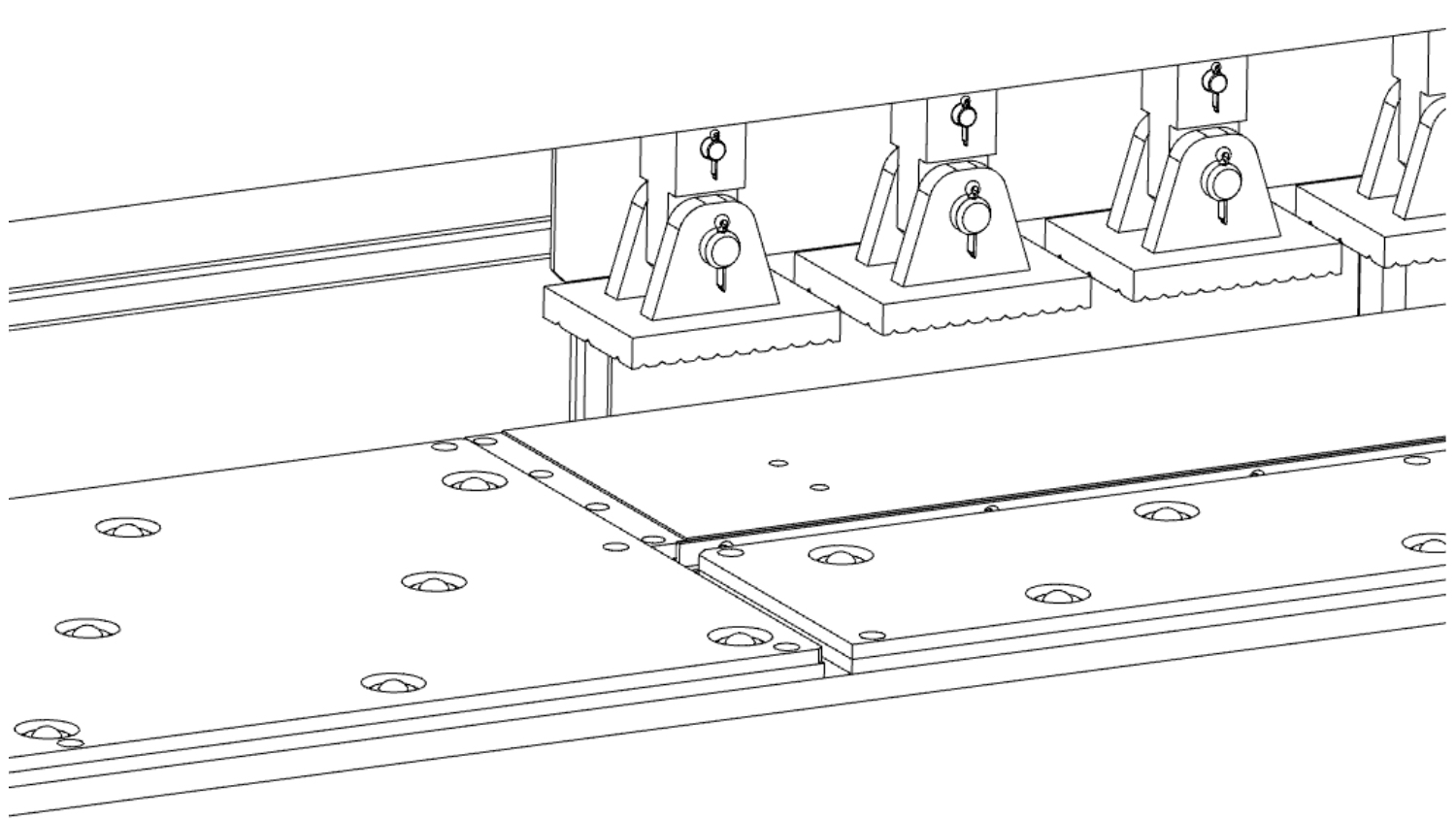

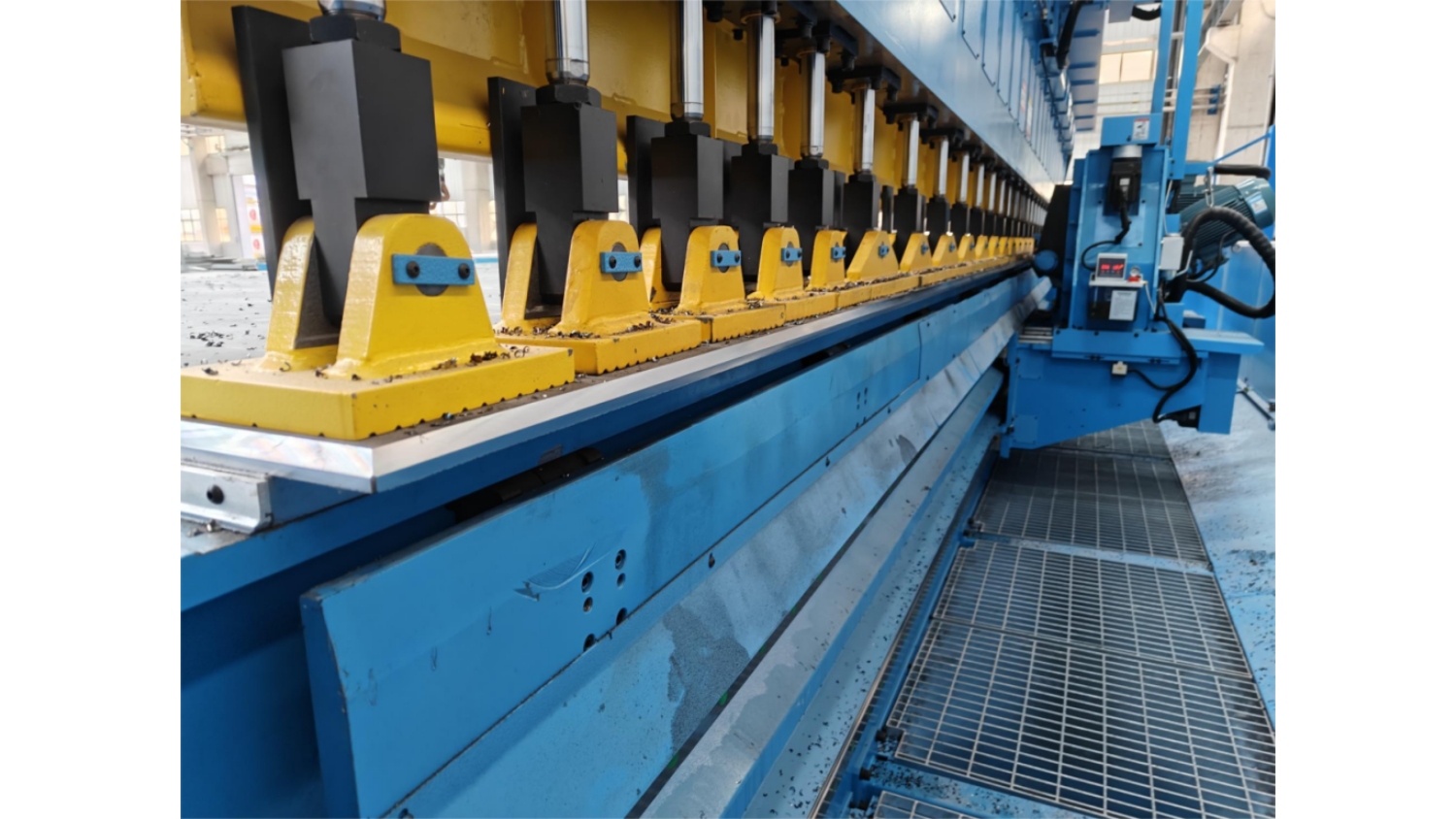

The CNC plate beveling machine has an automatic material blocking system, which uses hydraulic pressure to fix the plate. The positioning baffle of this machine is a whole block type, divided into two sections, each with a length of 2 meters, maintaining synchronous rise and fall;After the operator inputs the beveling parameters on the touch screen, they can start with one key to perform beveling operations on the workpiece. It is fully automated, the baffle can automatically evade after cutting processing begins, reducing the need for manual intervention and minimizing the risk of human error.

This is also the first step in the operation of the milling machine.

High Efficiency:

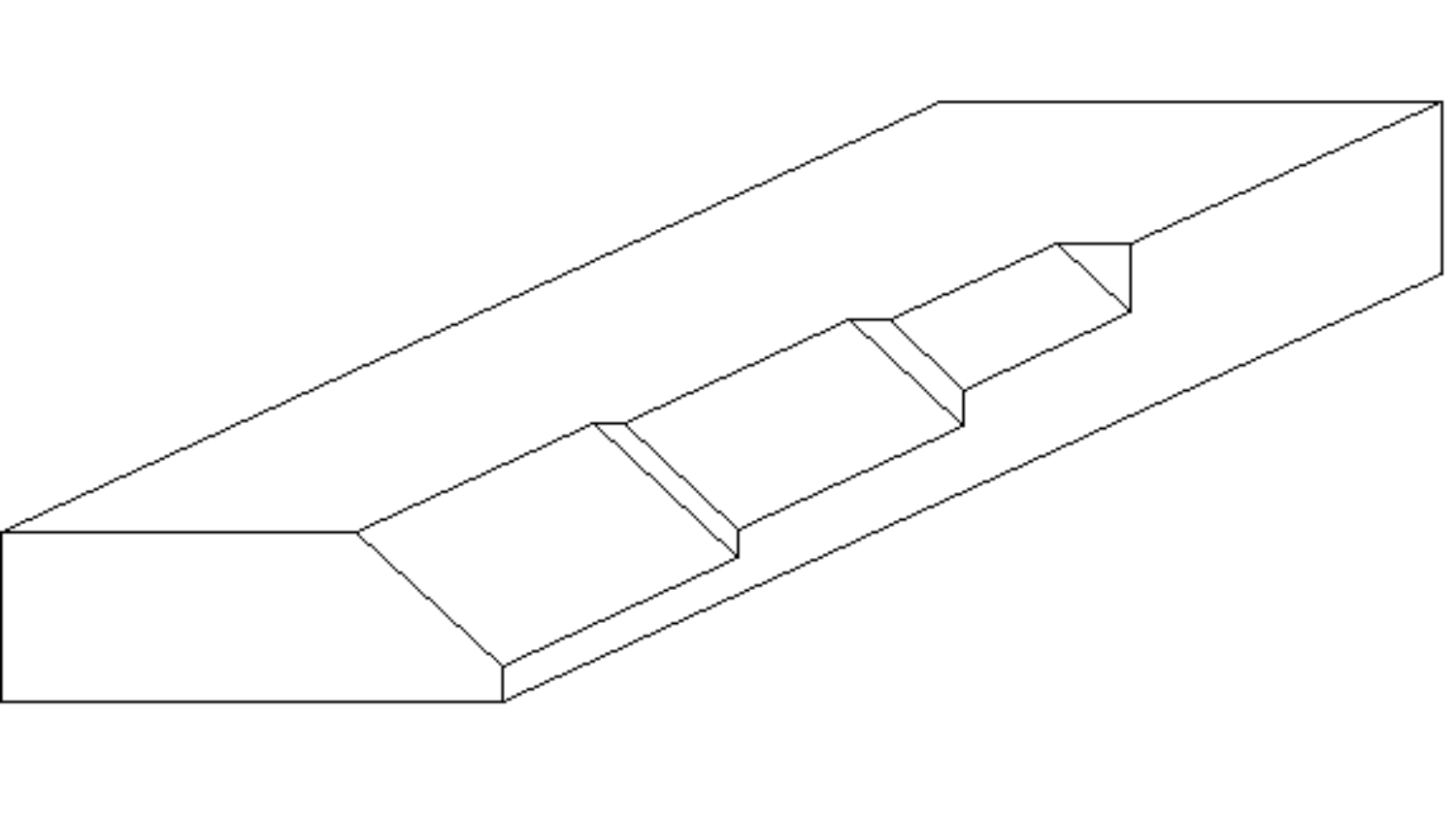

The motion axes of the machine are controlled by servo drive, and the upper and lower spindles can process multiple bevel types simultaneously; such as K, V, L, J/U, and I, and can be automatically completed by selecting the bevel type through the operation interface. When working with larger bevels, the control system can automatically calculate the subsequent layered cutting; Easy storage and retrieval of processing parameters;

Unique spindle speed and spindle feed automatic speed regulation function, which can be operated by personnel without metal cutting experience;

At the same time, the equipment is equipped with a knife disc for blade replacement and inspection operations, as well as a system fault self-diagnosis function; Key transmission components are automatically lubricated and can be equipped with automatic collection of iron filings; This machine has complete bevel functions and more precise dimensions; All operations are intuitive, convenient, efficient.

Strong safety performance:

A large number of steel ball bearings are built into the workbench to make feeding and discharging operations easier;

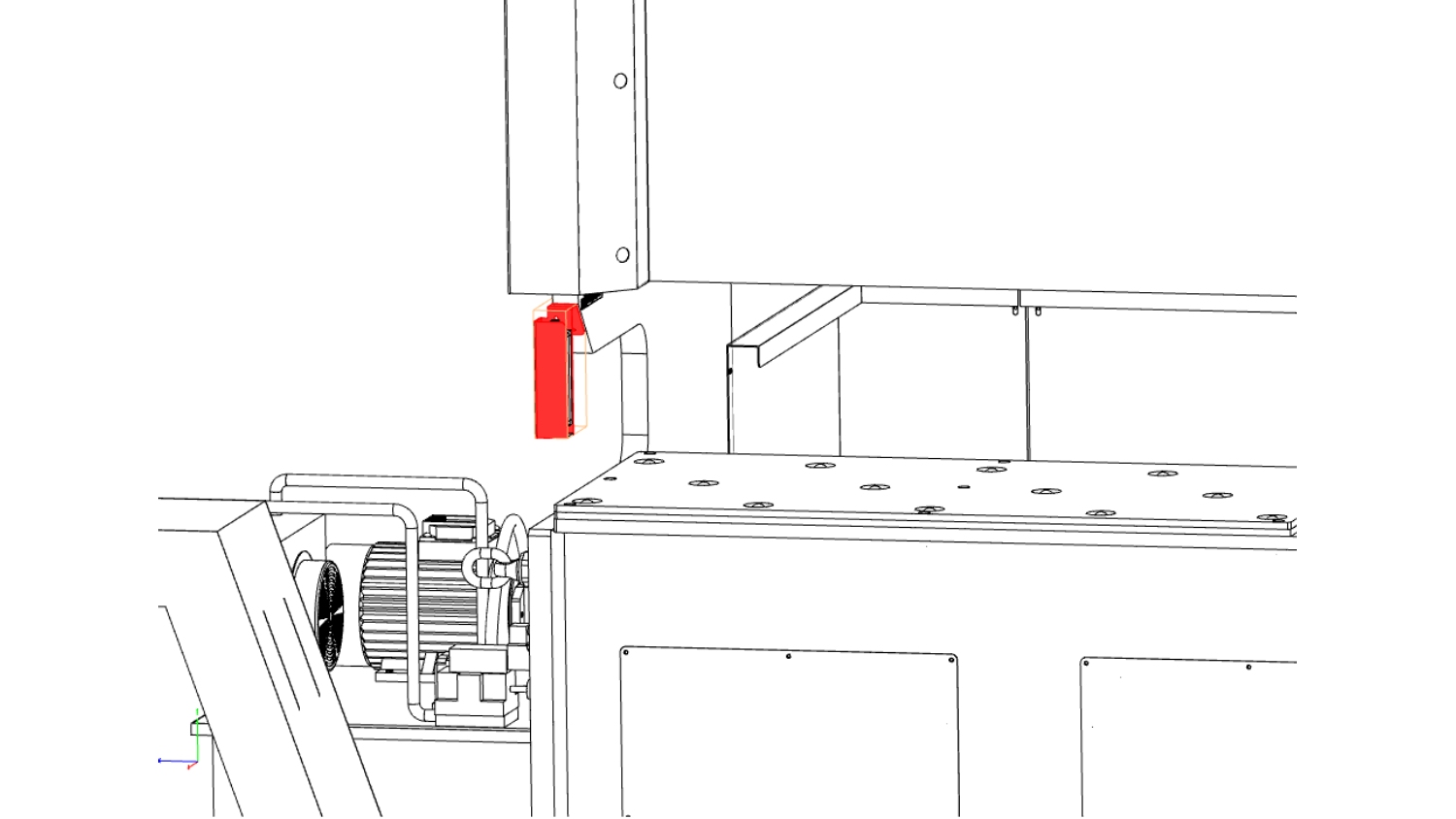

The feeding part of the workbench is equipped with the automatic protection function of the light curtain anti-rolling hand, and if any part of the operator mistakenly enters the area of the table during the pressing process, the hydraulic cylinder pressing foot will automatically stop the downward pressure; (The red part of the figure below shows the light curtain device)

When all processes are over, the spindle automatically returns to the origin position at high speed, and automatically starts all the processes again, the processing ends, each axis automatically returns to the zero point, and the pressing foot automatically rises;

High Precision: The GMM-X8000 utilizes advanced CNC technology to achieve precise edge milling, ensuring consistent quality across all container components.

The GMM-X8000 CNC plate Edge Milling Machine has proven to be a valuable solution for the tank container industry. Its high precision, efficiency, and cost-effectiveness make it an ideal choice for manufacturers looking to improve their edge milling process. By implementing this advanced machine, tank container manufacturers can achieve consistent quality, reduce costs, and meet the high production demands of the industry.

As the tank container industry continues to grow, the demand for advanced manufacturing solutions like the GMM-X8000 will only increase. Manufacturers who invest in such technologies will be better positioned to compete in the global market, delivering high-quality tank containers that meet the evolving needs of their customers.

NODHA with GIRET supply kinds of CNC plate edge milling machine as per the different requirement from customer. Below is another unit 12000MM machine will ready for a chemical machinery manufacture, we will supply more information, when it reach to customer site.

For more information, please contact us freely.

We are pleasure to provide a solution to you.