In modern industry, pipeline welding is an indispensable process, especially in the fields of oil, natural gas, electricity, chemical industry, etc. Pipe beveling machine, as a very important equipment in the pipeline welding process, plays a key role. The main task of the pipe beveling machine is to bevel the end face of the pipe to ensure that the end face of the pipe can be accurately docked with other pipes, valves and other components, thereby ensuring the strength and sealing of the welded joint. Therefore, choosing a suitable pipe beveling machine is crucial to improving work efficiency, reducing costs and ensuring processing quality. This article will discuss in detail how to choose a suitable pipe beveling machine, covering the type of equipment, selection criteria, technical parameters, precautions for use and other aspects.

First of all, before choosing a pipe beveling machine, we need to understand different types of beveling machines. Pipe beveling machines are mainly manual, semi-automatic and fully automatic, each with different applicable scenarios and advantages and disadvantages:

Manual pipe beveling machine: This type of beveling machine is generally suitable for small projects or low-frequency operations. It relies on manual control and manually adjusts the position of the beveling machine to complete the beveling of the pipe end face. The advantages of manual equipment are low cost, simple structure, and suitable for small batch processing. However, manual operation has low precision and requires high technical skills from the operator.

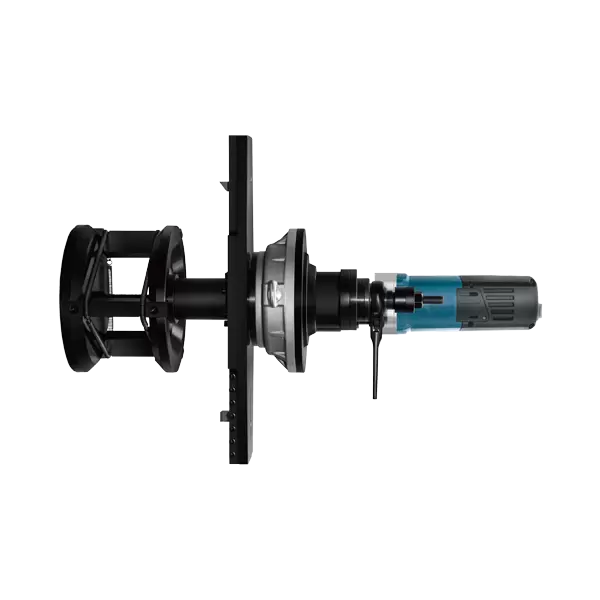

Semi-automatic pipe beveling machine: Semi-automatic beveling machine can automatically perform the cutting process, but the operator still needs to manually adjust some parameters or the positioning of the pipe. It is usually equipped with an electric motor, with a fast cutting speed, suitable for small and medium-sized batch production. Semi-automatic equipment can provide higher precision and efficiency, and is suitable for some high-precision pipe processing tasks.

Fully automatic pipe beveling machine: Fully automatic pipe beveling machine has the most advanced technology and can automatically complete the entire process of pipe beveling, including pipe positioning, angle adjustment, cutting, etc. Fully automatic equipment has high precision and extremely high efficiency, suitable for mass production and projects with high precision requirements. The disadvantage of fully automatic beveling machine is that it is more expensive and the maintenance cost of the equipment is also high.

According to different work requirements, users need to choose the type that best suits their production needs.

When choosing a pipe beveling machine, you first need to understand the processing capacity of the machine. This includes parameters such as the maximum diameter of the pipe, the maximum beveling depth and the beveling angle. Processing capacity directly determines the applicable scope of the pipe beveling machine, so when choosing, it is necessary to match it according to the size and shape of the processed pipe.

Maximum pipe diameter: Different models of pipe beveling machines can process different maximum pipe diameters. Usually, there are equipment for large-diameter pipes (such as thousands of millimeters) and small-diameter pipes. For large-diameter pipes, the beveling machine needs to have sufficient cutting capacity and stability to ensure processing quality.

Maximum beveling depth: The beveling depth is usually set according to the wall thickness of the pipe. Too large a depth may cause material waste, and too small a depth cannot guarantee the strength of the welding. Therefore, it is necessary to select equipment that can adjust the beveling depth according to actual needs.

Beveling angle: Common beveling angles are 30°, 45°, 60°, etc. Different welding requirements may require different beveling angles. When choosing, choose a suitable beveling machine according to the design requirements of the pipeline.

In addition to processing capacity, the technical parameters of the pipe beveling machine are also factors that need to be considered when choosing. Here are several key technical parameters:

Power and cutting speed: Power and cutting speed are key factors affecting the processing efficiency and quality of pipe beveling machines. Generally, the greater the power, the faster the cutting speed, and the higher the processing efficiency. However, it should be noted that excessively high cutting speeds may lead to a decrease in cutting quality, so the appropriate power and speed should be selected according to the specific situation.

Tool material and cutting accuracy: The material of the tool directly affects the cutting effect. Generally, high-hardness tools can remain sharp for a longer time and are suitable for pipe materials with higher hardness. Cutting accuracy also directly affects the quality of the bevel. Choosing high-precision equipment can reduce the subsequent processing and repair work.

Hydraulic or pneumatic system: Some high-end pipe beveling machines are equipped with hydraulic or pneumatic systems for automatically adjusting pressure and feed speed to improve the stability and efficiency of the equipment. The hydraulic system is particularly important for the processing of large-diameter pipes, which can maintain a stable cutting pressure and ensure processing quality.

Adjustability: Different pipes have different processing requirements. Choosing a pipe beveling machine that can flexibly adjust the cutting angle, depth and speed can effectively improve work efficiency and processing quality.

Pipe beveling machines are usually driven by electric, pneumatic and hydraulic. Different drive modes are suitable for different working environments and needs:

Electric drive: Electric-driven pipe beveling machines are often used in factories and workshops, and can provide stable power output, suitable for most conventional beveling processing needs.

Pneumatic drive: Pneumatic-driven equipment is suitable for places with harsh working environments and sufficient air sources. The advantages of pneumatic equipment are high power, easy operation and environmental protection, which are suitable for some scenes that require mobile operation.

Hydraulic drive: Hydraulic-driven equipment is usually used for processing large-diameter pipes. The hydraulic system can provide stable power and is suitable for high-precision and high-pressure processing tasks.

The ease of operation and maintenance of the pipe beveling machine is also an important consideration when choosing. Complex operating systems and difficult-to-maintain equipment may increase the cost and time of use. For some pipe beveling machines with more complex equipment, ensure that the operation interface is simple and easy to understand, and maintenance is convenient.

Operation interface: Choosing a beveling machine with a simple operation interface can reduce the technical requirements for operators and improve work efficiency. Modern pipe beveling machines are generally equipped with CNC systems. Users only need to set processing parameters according to their needs, and the equipment can automatically complete the processing tasks.

Maintenance: The maintenance cycle and difficulty of the pipe beveling machine directly affect the cost of use. The equipment needs to regularly check the working status of components such as tools, hydraulic systems, and electrical systems to ensure their normal operation. Choosing equipment that is easy to maintain and easy to replace accessories can effectively reduce the subsequent maintenance costs.

Cost-effectiveness is one of the most important factors when choosing a pipe beveling machine. When choosing equipment, it is necessary to comprehensively consider multiple aspects such as price, performance, and maintenance costs to avoid blindly pursuing low prices and sacrificing the quality and performance of the equipment. Generally speaking, the price of the equipment is proportional to its performance, but there are also some cost-effective equipment on the market that can provide relatively high performance and low prices.

Brand and after-sales service are factors that cannot be ignored when choosing a pipe beveling machine. Some well-known brands are usually able to provide high-quality equipment and more reliable after-sales service. High-quality after-sales service can ensure that problems with the equipment during use can be solved in a timely manner, reducing downtime.

Choosing the right pipe beveling machine is the key to improving production efficiency and ensuring the quality of pipeline welding. By understanding the basic types, processing capabilities, technical parameters, drive methods, ease of operation and maintenance of pipe beveling machines, users can choose the equipment that best suits their needs. When choosing, it is necessary to weigh price and performance according to actual needs to ensure that the equipment can meet production requirements and provide long-term and stable services.