Home > Events > Company News > VIP Client from Israel visit NODHA factory - in-depth experience of intelligent welding

Home > Events > Company News > VIP Client from Israel visit NODHA factory - in-depth experience of intelligent welding On March 27, 2025, NODHA factory welcomed an important customer, a veteran enterprise member with more than 90 years of profound experience in the fields of welding, cutting and heat treatment in Israel. They visited NODHA collaborative robot welding project and intelligent equipment for spot welding, tube-to-tube welding and tube-to-sheet welding.

In the technical seminar that lasted a whole afternoon, the two sides had in-depth exchanges on topics such as multi-process integration and localization upgrades. This scene can't help but remind people of the ten-year cooperation between NODHA and customers. Since the first order was completed in 2012, the years have witnessed the gradual deepening of mutual trust. The consistent and firm choice of customers is the greatest compliment to NODHA and our belief in moving forward.

For more than ten years of trust, NODHA and customers have grown together and achieved each other. This friendship and trust is an invaluable honor for NODHA, and it also makes us look forward to and look forward to future cooperation.

In the product display area of the NODHA facility, NODHA's technical engineers demonstrated three core welding technologies on site:

1. Collaborative robot display area

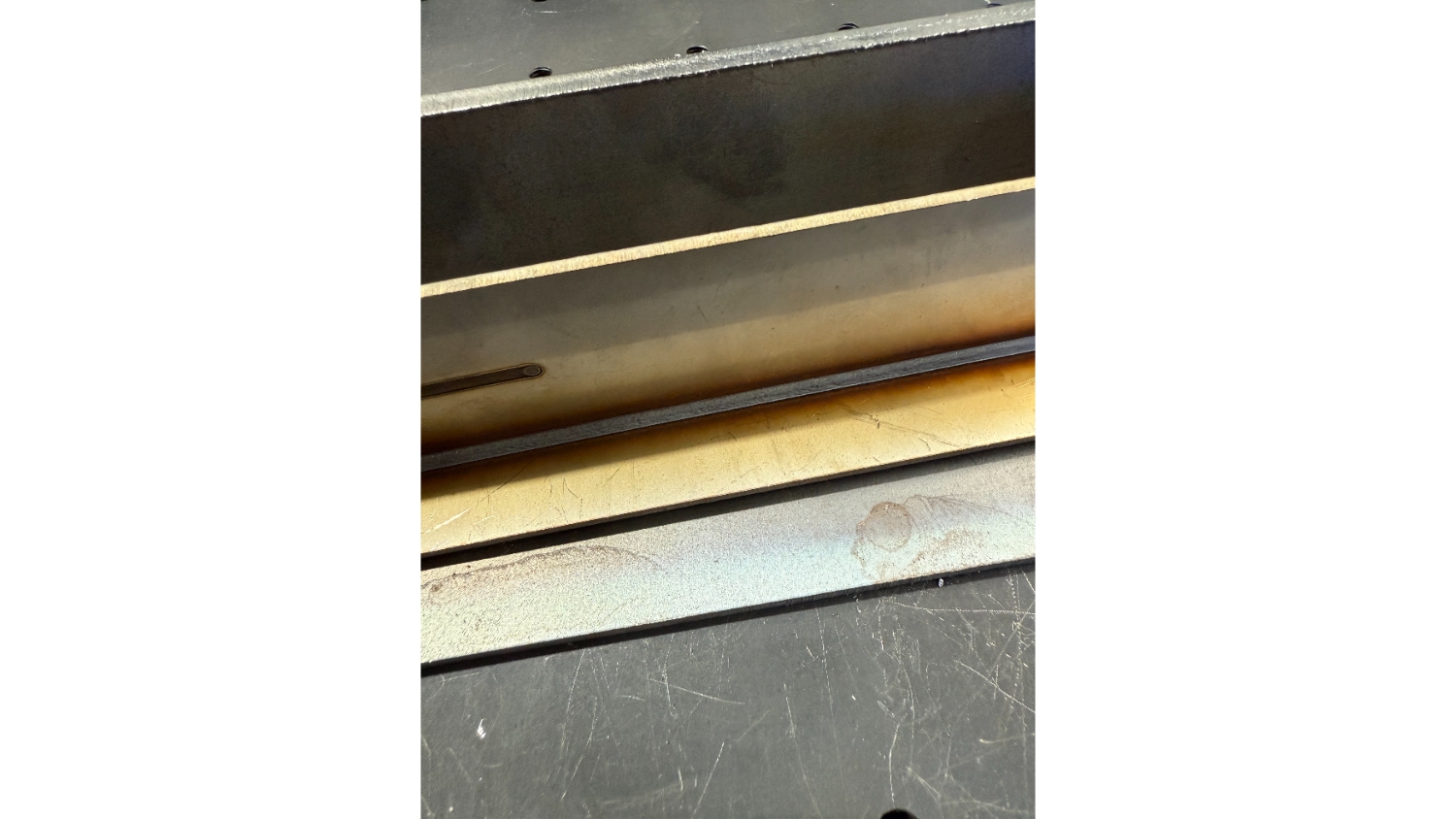

Efficient two-protection welding: equipped with 0.8mm copper-plated solid core welding wire, 12m/min high-speed welding is achieved on 6mm carbon steel plates

Precision laser welding: using blue light laser (450nm wavelength), the weld width control accuracy reaches ±0.1mm

Customer representatives personally operated the collaborative robot to complete complex spatial trajectory welding tests under simulated working conditions. "The sensitivity of human-machine collaboration is very high," the customer said after completing the operation, and the customer also made optimization suggestions for product adjustments and upgrades. During the communication session, NODHA technicians responded on the spot, adding a Hebrew operating interface for the collaborative robot to improve the localization adaptation level.

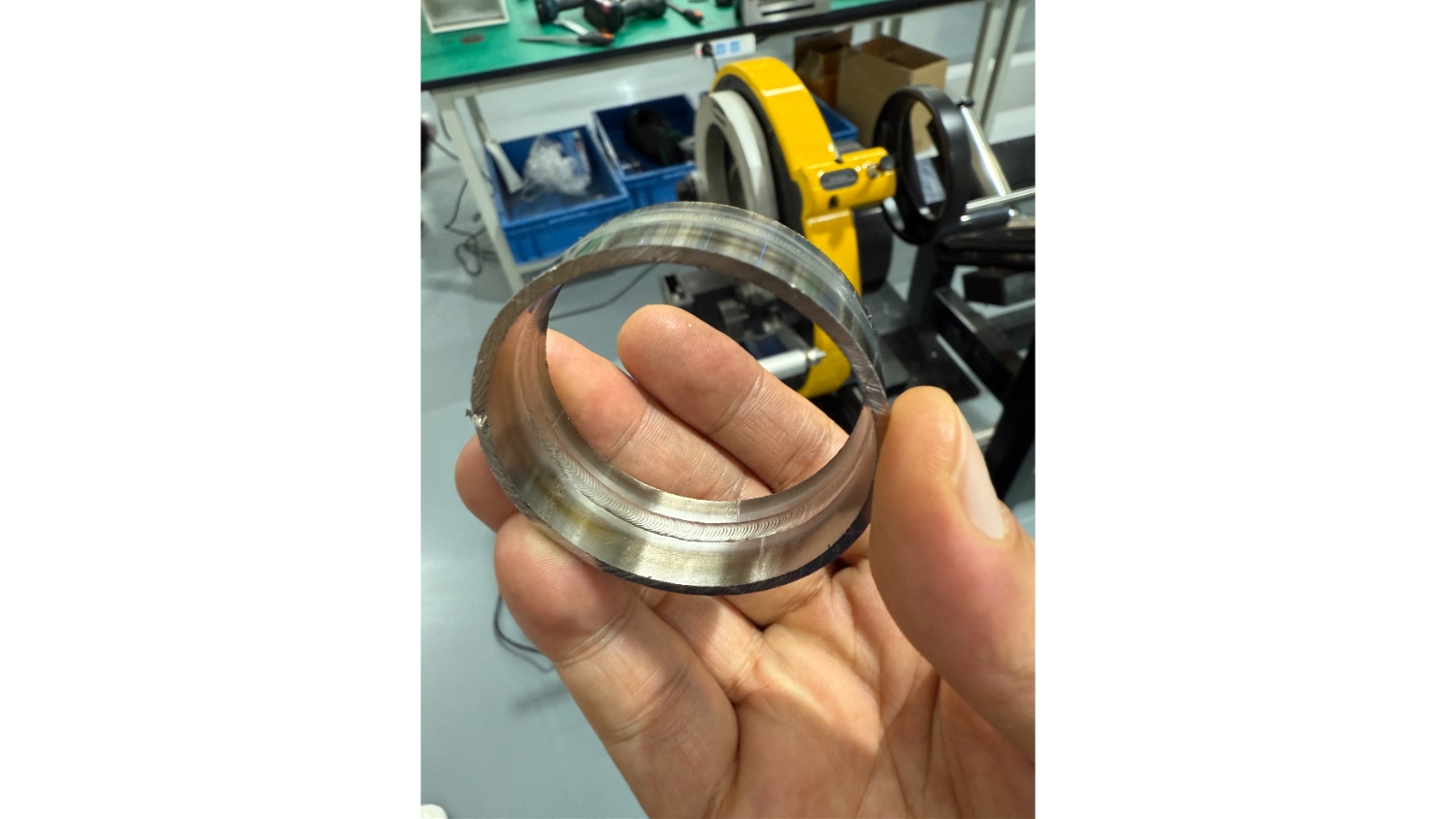

2. Pipe welding equipment

The customer operated the TS8 pipe-to-pipe welder and the TS80 tube-to-sheet welder on site, focusing on testing the welding process of 2mm wall-thick stainless steel pipes. NODHA technicians demonstrated the differentiated applications of P200 (5-200A) and P400 (10-400A) power supplies on site, and the customer particularly affirmed the on-site construction efficiency of P400.

At the end of the inspection, the two parties took a group photo at the gate area of the NODHA factory. NODHA is very grateful for the customer's visit.