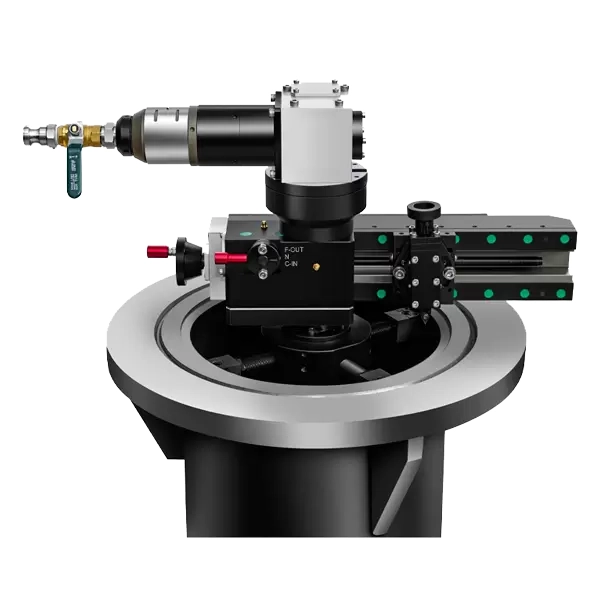

Flange facing machine is a common industrial equipment used to process the end face of flange to ensure the flatness and sealing of flange. In order to ensure the normal operation of flange facing machine and extend its service life, correct maintenance is very important. This article will introduce the maintenance guide of flange facing machine.

Cleaning: Clean the various parts of flange facing machine regularly, especially the cutter and fixture. Use brush and detergent to remove chips and oil stains to keep the machine clean.

Lubrication: The various bearings and transmission parts of flange facing machine need to be lubricated regularly to reduce wear and friction. Use appropriate lubricating oil or grease to lubricate the machine and operate according to the instructions in the manual.

Inspection: Check the various parts of flange facing machine regularly to see if they are operating normally and whether there is any looseness or wear. If any problems are found, repair or replace them in time.

Calibration: The accuracy of flange facing machine has a great influence on the processing effect, so it needs to be calibrated regularly. According to the instructions in the manual, use professional calibration tools to calibrate the machine to ensure that its accuracy meets the requirements.

Replace the tool: The tool is the core component of the flange facing machine. It will wear out after a long time of use, affecting the processing effect. According to the instructions in the user manual, replace the tool regularly to ensure the processing quality.

Replace the drive belt: The drive belt is an important transmission component of the flange facing machine. It will loosen or wear out after a long time of use. Check the status of the drive belt regularly and replace it in time if any problems are found.

Clean the cooling system: The flange facing machine needs to use coolant to cool the tool and workpiece during processing to reduce friction and heat. Clean the cooling system regularly to remove impurities and sediments to ensure the smoothness and cleanliness of the coolant.

Check the electrical system: The electrical system of the flange facing machine is the key to its normal operation. Regularly check whether the electrical system connection is firm, whether the wires are worn, and whether the switches and buttons are normal. If problems are found, repair or replace them in time.

The tool is stuck: If the tool is stuck during processing, stop the machine immediately for inspection. It may be caused by insufficient cutting fluid, tool wear or loose fixture. The solution is to add cutting fluid, replace the tool or re-clamp the fixture.

Processing quality declines: If the processing quality declines, it may be caused by tool wear, loose fixtures, or inaccurate machine calibration. The solution is to replace the tool, re-clamp the fixture, or perform machine calibration.

Electrical failure: If a fault is found in the electrical system, the machine should be stopped immediately for inspection. It may be caused by short circuit of wires, damaged switches, or motor failure. The solution is to repair or replace the faulty parts.

When operating the flange facing machine, you should wear a safety helmet, goggles, and protective gloves to ensure your own safety.

When cleaning and maintaining the flange facing machine, you should first cut off the power supply to avoid electric shock accidents.

When replacing the tool and drive belt, you should first stop the machine and wait for the machine to stop completely to avoid accidental injuries.

When calibrating the machine, you should follow the instructions in the manual to avoid machine damage or personal injury caused by misoperation.

In summary, proper maintenance can ensure the normal operation of the flange facing machine and extend its service life. Through daily maintenance, regular maintenance, and troubleshooting, you can keep the machine in good condition and improve processing efficiency and quality. At the same time, follow safety precautions to ensure the safety of operators. I hope the maintenance guide in this article is helpful to everyone.

As a flange facing machine exporter, we are committed to providing high-quality products and excellent services to meet the needs of global customers. We have advanced production equipment and technical team, capable of producing flange facing machines of various specifications and models to meet the needs of different industries.