Flange facing machine is a special equipment for processing flange end faces, which is widely used in the manufacturing industry. When purchasing flange facing machines, price is an important consideration. However, the price of a flange facing machine is affected by many factors. This article will discuss these factors to help readers better understand the price composition of flange facing machines.

Brand is one of the important factors affecting the price of flange facing machines. Well-known brands usually have high market recognition and good reputation, and their products are often more guaranteed in terms of quality, performance and after-sales service. Therefore, the price of flange facing machines of well-known brands is relatively high. For example, some well-known mechanical equipment brands in the market, such as Zhuoyang Machinery and Aotai Machinery, have a high market share of flange processing machine products and relatively high prices.

Technical parameters are the key factors that determine the performance of flange facing machines and are also important indicators that affect prices. The following are several main technical factors:

2.1 Processing range and clamping range

The processing range and clamping range determine the applicable scope of the equipment. Different models of flange facing machines are suitable for flanges of different sizes. The larger the processing range, the wider the applicable scope of the equipment, and the higher the price.

2.2 Drive mode

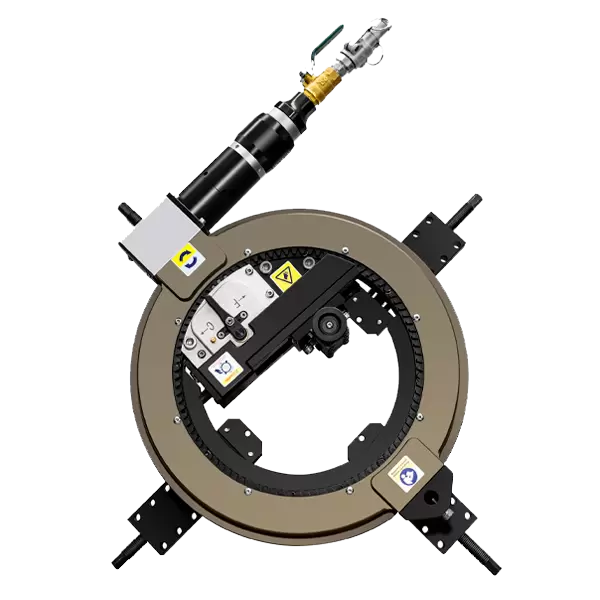

The drive modes of flange facing machines are mainly manual, pneumatic, hydraulic and CNC. Among them, the manual drive mode is the simplest and the lowest price; the pneumatic and hydraulic drive modes are relatively complex and moderately priced; the CNC drive mode is the most expensive because of its high precision and high efficiency.

2.3 Speed and power

The speed and power of the equipment directly affect its processing efficiency and capacity. Generally speaking, the higher the speed and the greater the power of the equipment, the higher the processing efficiency, but the price also increases accordingly. For example, some high-end models of flange processing machines can reach thousands of revolutions per minute, and the power is also large, so the price is higher.

2.4 Control mode

The control mode of flange facing machines is divided into manual, semi-automatic and fully automatic. The manual control mode is simple but inefficient and has a low price; the semi-automatic and fully automatic control modes are expensive because of their high efficiency and high precision. For example, the CNC flange facing machine adopts a fully automatic control mode, and the price is significantly higher than the manual and semi-automatic models.

In addition to the basic technical parameters, the functional configuration of the flange facing machine is also an important factor affecting the price. The following are several common functional configurations:

3.1 Modular design

Some high-end models of flange end facing machines are equipped with additional functions, such as automatic feed, multi-gear adjustment, high-precision measuring tools, etc. These functions can greatly improve the processing accuracy and efficiency of the equipment, but will also increase the cost of the equipment.

IV. Market demand and supply

Market demand and supply are also one of the important factors affecting the price of flange end facing machines. When the market demand is strong, the price of equipment tends to rise; conversely, when the market is oversupplied, the price will fall. In addition, fluctuations in raw material prices, changes in labor costs, and adjustments to policies and regulations will also have an impact on equipment prices.

After-sales service is one of the important factors that users need to consider when choosing a flange end facing machine. Perfect after-sales service can provide users with technical support, repair and maintenance services to ensure the normal operation of the equipment. Well-known brands usually do better in after-sales service, which is also one of the reasons why their products are more expensive.

In summary, the price of flange end facing machines is affected by many factors, including brand, technical parameters, functional configuration, market demand and supply, and after-sales service. When purchasing a flange facing machine, users should consider these factors comprehensively according to their own needs and budget, and choose the product with the best cost performance. At the same time, it is recommended that users choose well-known brands and manufacturers with good after-sales service to ensure the quality and user experience of the equipment.

As a flange facing machine manufacturer from China, we are committed to providing high-quality, high-performance equipment. Our product line covers a variety of models and specifications to meet the diverse needs of different customers. At the same time, we also pay great attention to after-sales service, providing customers with timely and professional technical support and maintenance services to ensure the long-term and stable operation of the equipment.