Home > Application > On Site Machining Equipment > Application Case of Pipe Beveling Cold Processing Solution

Home > Application > On Site Machining Equipment > Application Case of Pipe Beveling Cold Processing Solution

I. Project Background

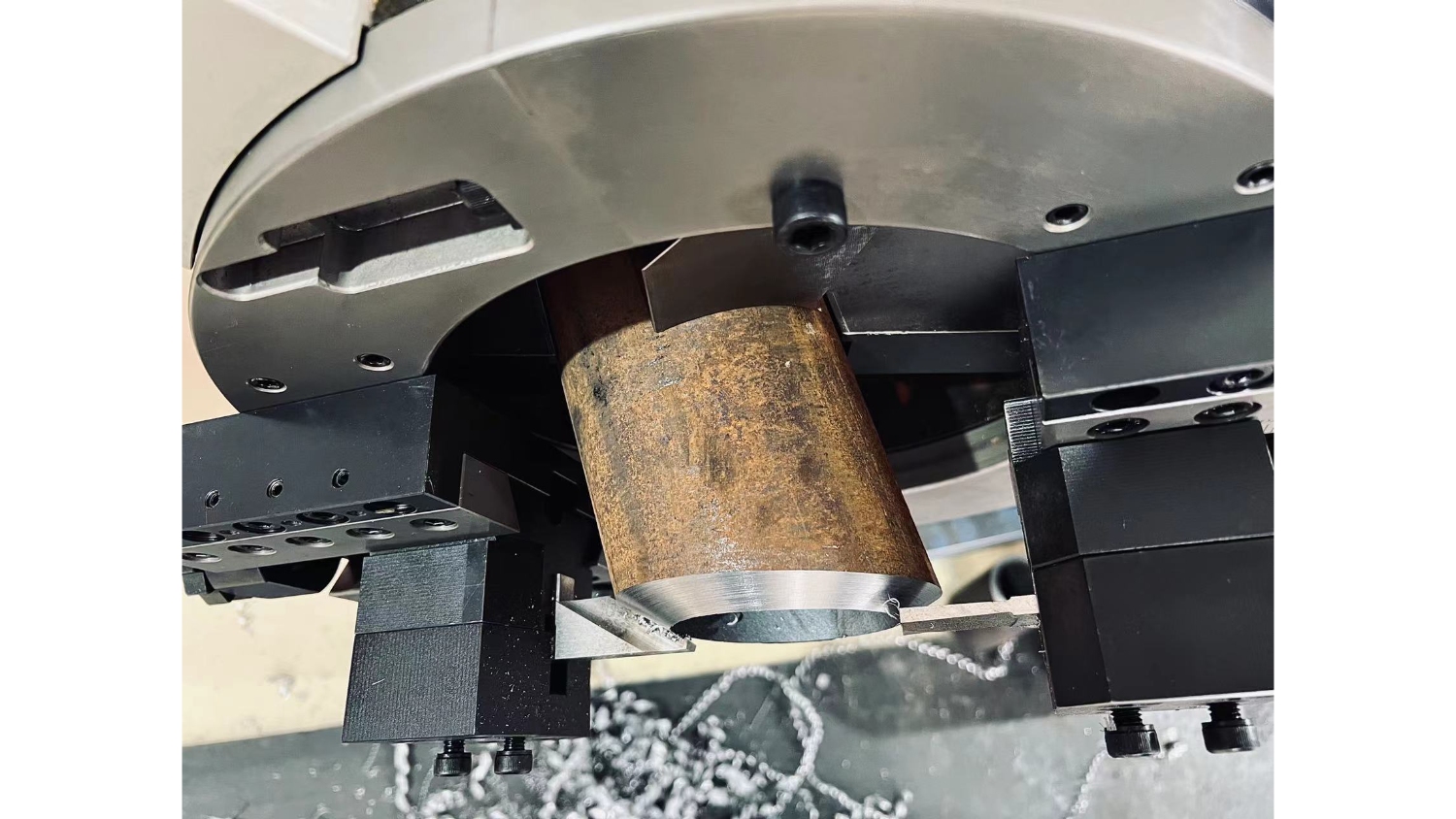

In the past 2 years, NODHA has provided customized cold cutting and beveling machines for 3 customers, two of which are from China and the other is from Lebanon. So when the Polish company MAKROMOR told us that we needed to process OD101.4×20mm carbon steel pipes, with the requirements of: diagonal cutting angle 73.5°/77°, simultaneous completion of 45° beveling processing, and single-shift production capacity ≥80 pieces, NODHA provided a solution. After a month, we have now completed the customized parts and the first trial run.

II. Industry Challenges

Traditional flame/plasma cutting has significant defects in pipe beveling processing: the heat affected zone is up to 1.2mm, resulting in welding stress concentration, the bevel surface roughness Ra≥25μm, requiring secondary grinding, and the angle deviation is ±2°, affecting the assembly accuracy.

III. Technological breakthrough

Achieved through 3D modeling and dynamic compensation technology

Dual-axis linkage cutting system: X-axis ±120mm feed, B-axis ±90° rotation

Intelligent angle compensation algorithm: cutting angle error ≤±0.5°

Modular tool set: carbide blade life up to 500 cuts

IV. Customer feedback

On June 24, 2022, the customer renewed the purchase and commented: "The equipment has achieved 24-hour continuous operation, and has steadily produced 80 precision pipes per week and sent them to Denmark. The welding qualification rate has increased from 82% to 97%, and the annual maintenance cost has been reduced by 45%."