Beveling machines are now essential tools in various industrial environments and play a vital role in preparing metal edges for welding and other processes. The versatility and efficiency of beveling machines are important reasons why they have become essential tools in multiple industries, especially in boiler manufacturing and chemical plants.

1. Beveling machines in boiler manufacturing

In boiler manufacturing, precision and quality are essential. The role of the beveling machine is to create precise bevels on the edges of metal plates that are welded together to form boiler components. The beveling process ensures that the edges fit perfectly, which is essential to maintaining the structural integrity and safety of the boiler. The advantages of using a beveling machine in boiler manufacturing are: first, it can improve the quality of welding. It provides clean and precise bevels, allowing welds to penetrate better and joints to be stronger; second, it improves efficiency. The beveling machine can quickly process a large amount of material and significantly shorten production time; third, it ensures consistency, ensuring that the bevel angle and depth are consistent, meeting high-quality manufacturing standards.

2. Beveling machines in chemical plants

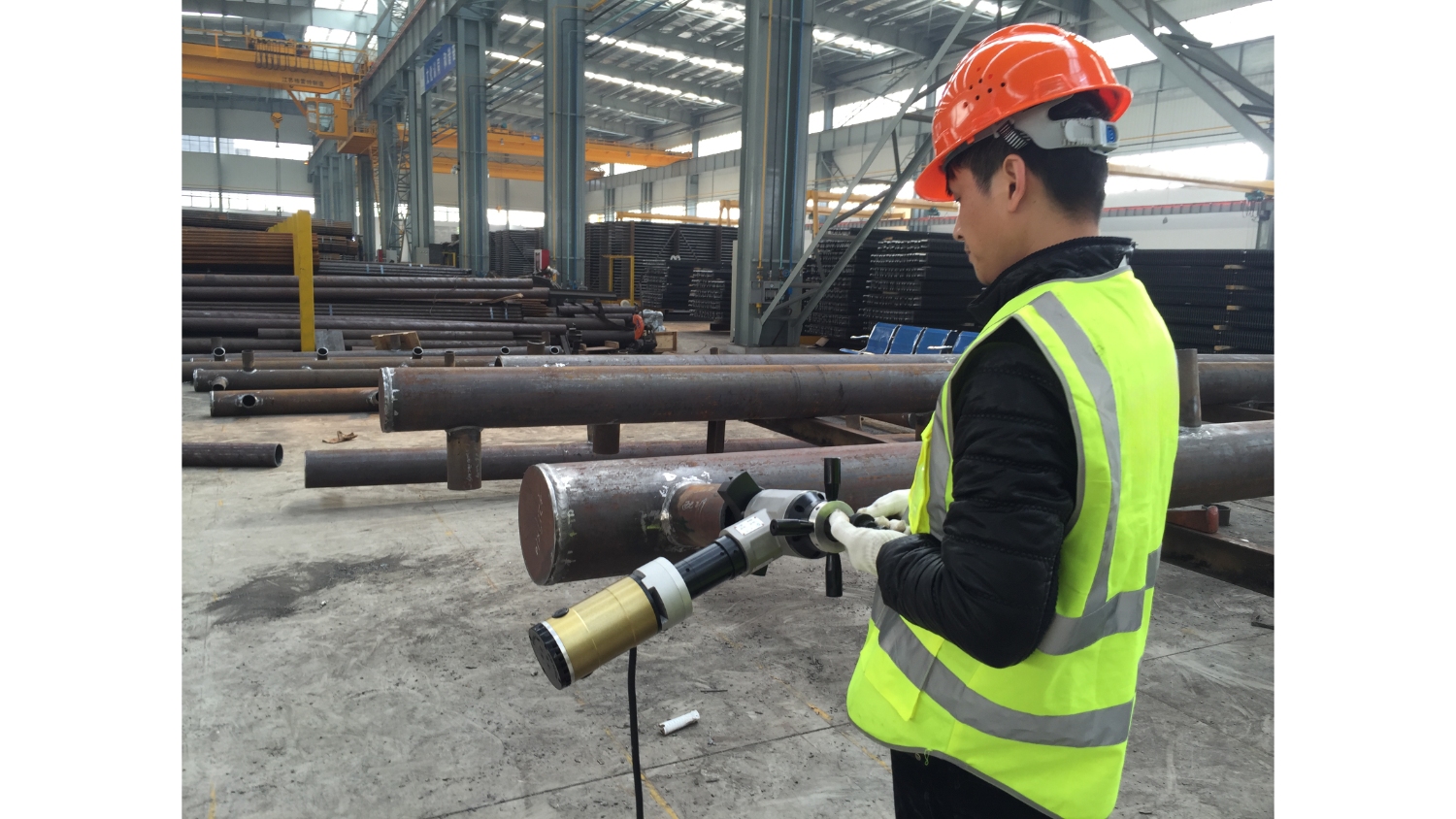

The risk factor of chemical plants requires careful handling and processing when handling various required materials. Beveling machines are used to prepare pipe edges and other components for welding, ensuring they can withstand the high pressure and corrosive environments common in chemical processing. Using beveling machines in chemical plants is not only safer, but also adaptable. Beveling machines can be adjusted to different materials and thicknesses to adapt to various components in chemical plants. In addition, beveling machines are easier to maintain, which can maintain the integrity of the pipeline system, reduce failures, and reduce maintenance costs.

Beveling machines are important tools in boiler manufacturing and chemical plants. The precise bevels formed by beveling machines improve the quality and safety of welded joints. As technology advances, the efficiency and functionality of beveling machines will continue to develop, further consolidating their role in the modern manufacturing industry.