Home > Application > On Site Machining Equipment > Steam Pipeline: 10″x30mm 12Cr1MoV Pipe Cutting and Beveling

Home > Application > On Site Machining Equipment > Steam Pipeline: 10″x30mm 12Cr1MoV Pipe Cutting and Beveling

I. Project Background

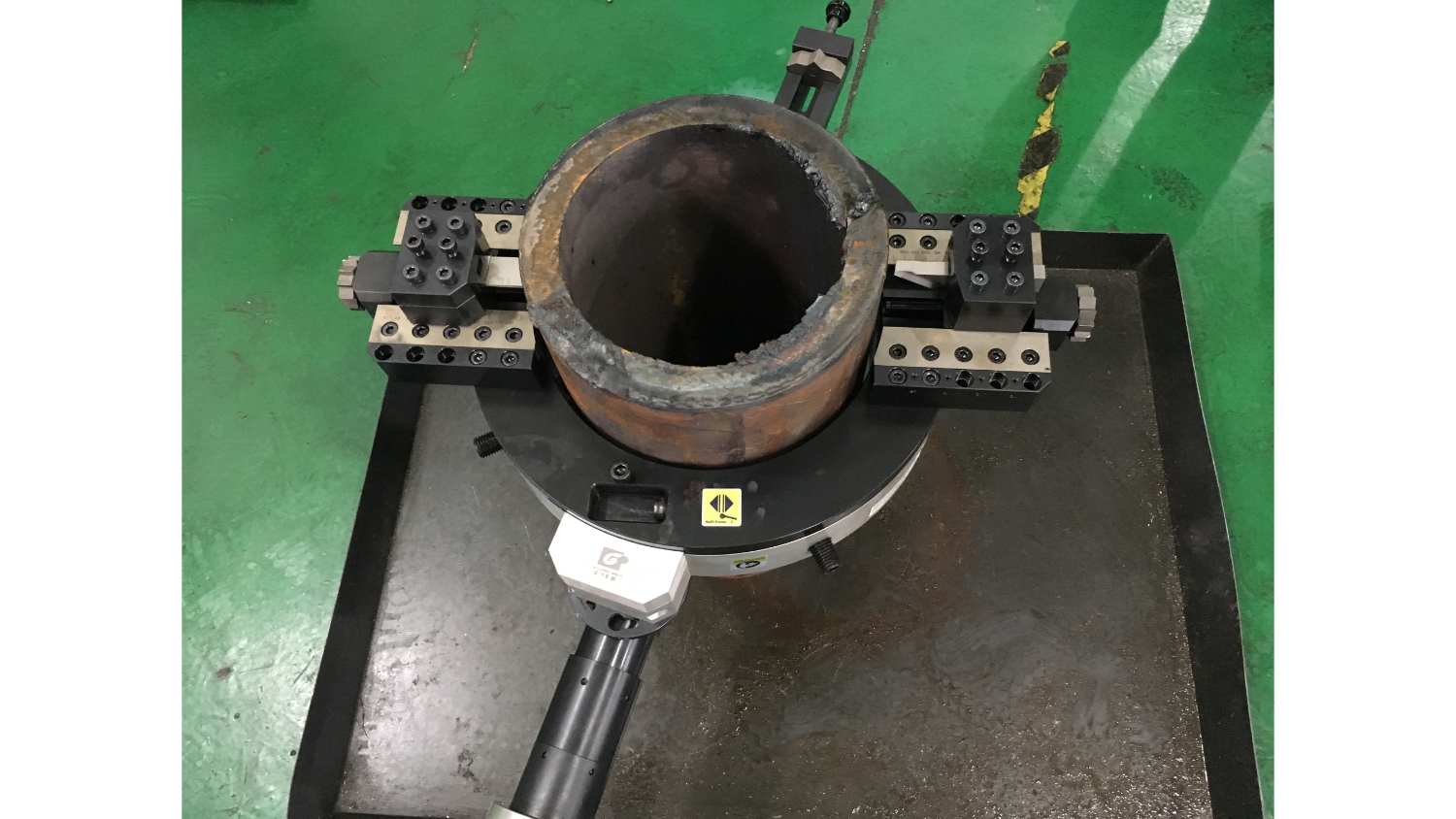

In September 2016, NODHA successfully completed the project for the special processing requirements of 12Cr1MoV high-pressure steam pipes (pipe diameter 10 inches/wall thickness 30mm) in a power plant construction project in Wuhu, Anhui. The alloy pipe has extreme characteristics of Rockwell hardness HRC38-42 and tensile strength ≥550MPa. The customer had previously tried three equipment suppliers and all failed.

II. Process parameter optimization

Cutting speed improvement reduces tool loss

Feed rate 0.15mm/r 0.08mm/r Surface roughness reduction

Cooling method External cooling spray Internal and external composite cooling Extend tool life

III. Implementation results

10-inch pipe, wall thickness 30mm, NODHA finally took 40 minutes to successfully complete this work.

IV. Project value

Measured data shows that compared with traditional processes: processing efficiency is improved, tool costs are reduced, and rework rate is reduced to zero.