Home > Application > On Site Machining Equipment > 120mm walled pipe ------ Maintenance job at Power plant

Home > Application > On Site Machining Equipment > 120mm walled pipe ------ Maintenance job at Power plant

I. Project Background

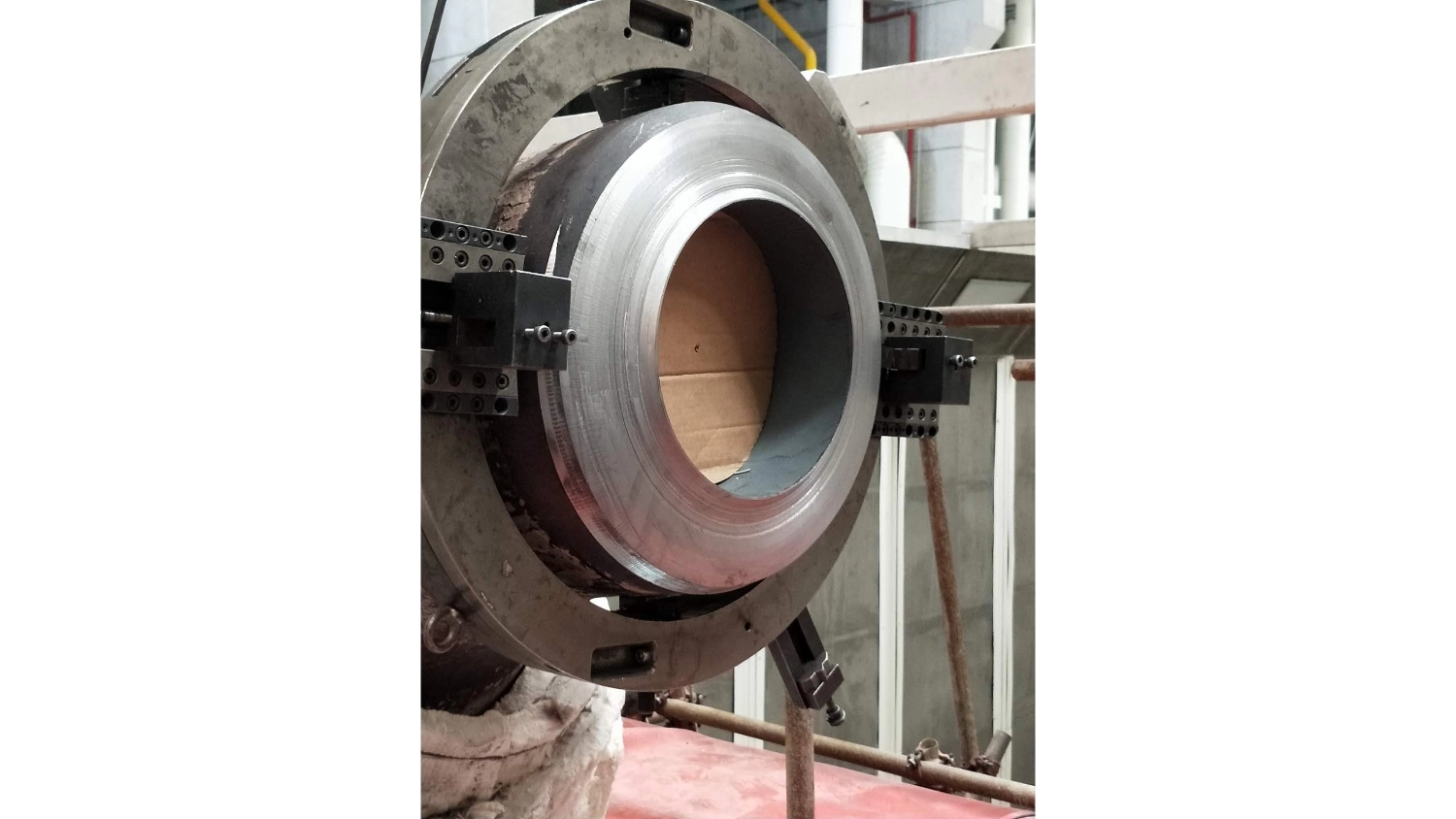

During the overhaul of a supercritical unit in a thermal power plant, it is necessary to cold cut and groove the 22-inch (Φ559mm) P92 steel main steam pipe (wall thickness 120mm). P92 steel is a martensitic heat-resistant steel with a strength of σb≥620MPa. Traditional flame cutting is prone to cracks in the heat-affected zone, while mechanical processing faces difficulties such as high cutting force and short tool life.

II. Technical Challenges

Material properties: high hardness (HB250-300) leads to a 30% increase in cutting resistance; high-temperature temper brittleness requires the cutting temperature to be controlled within 300℃

Dimensional accuracy: groove angle, flatness, surface roughness;

III. Customer feedback

NODHA equipment has achieved a perfect balance of high precision, high efficiency and low cost in this case.