I. Technical challenges

Extraordinary wall thickness, 90+mm wall thickness exceeds the capacity of standard equipment, and the wall thickness increases, making it difficult for traditional cutting methods to complete the task efficiently and accurately

Material hardness and work hardening trend lead to rapid wear of the tool, low cutting efficiency, and difficult to ensure cutting quality. The cut is prone to unevenness and deformation.

Harsh environment, some industrial scenarios with strict requirements on material performance, such as petrochemical, electric power and energy, etc., the pipes after thermal cutting may not meet the use standards

II. Working scope

Cutting and beveling thick-walled pipes (wall thickness 90+mm)

Material: duplex stainless steel UNS S31803 (yield strength ≥550 MPa)

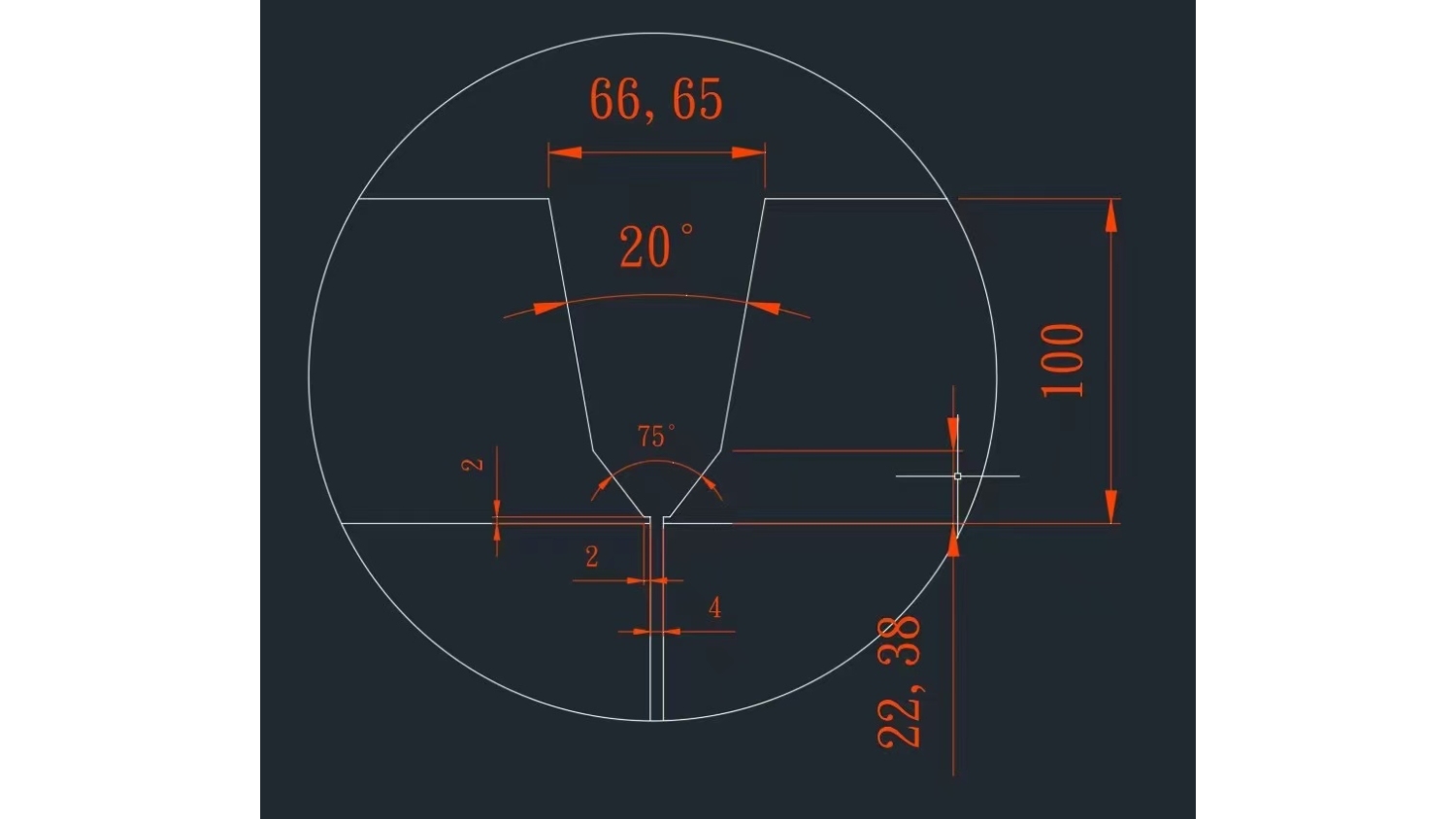

Beveling specifications: composite beveling

III. Technical solutions

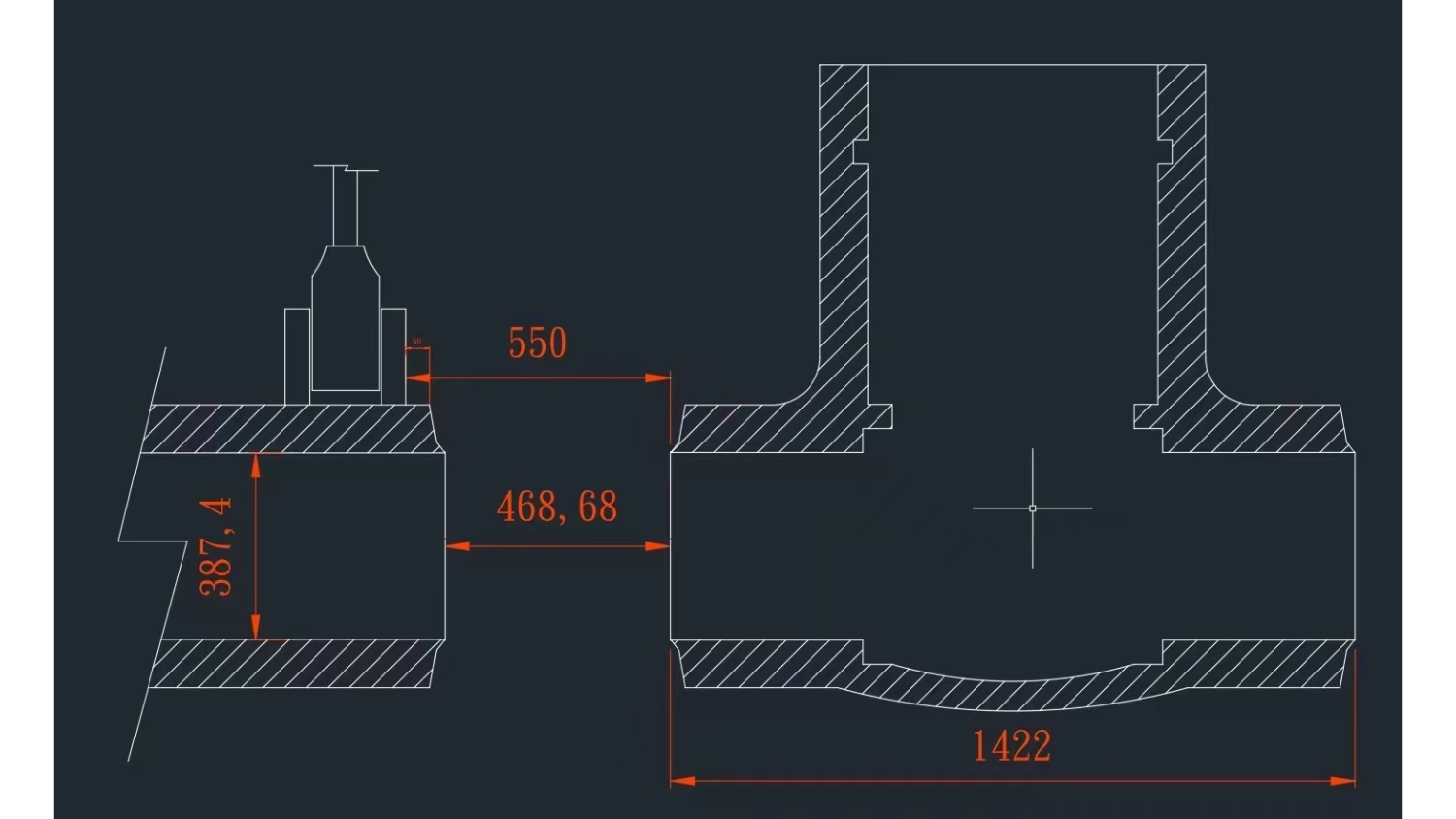

Equipment configuration: external clamp beveling machine, composed of a rotating ring and a fixed ring, can be easily installed on the pipe.

Advantages: small size, light weight, easy to move and install in different work sites, and can work flexibly

IV. Implementation results

Greatly shortened the construction period

Reduce tool wear and improve cutting quality

If you have any questions please send an email to: doria.zhu@nodha.com Or call: +86 15102105304